About 4-Axis CNC Machining Services

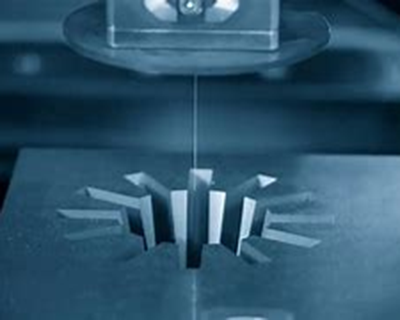

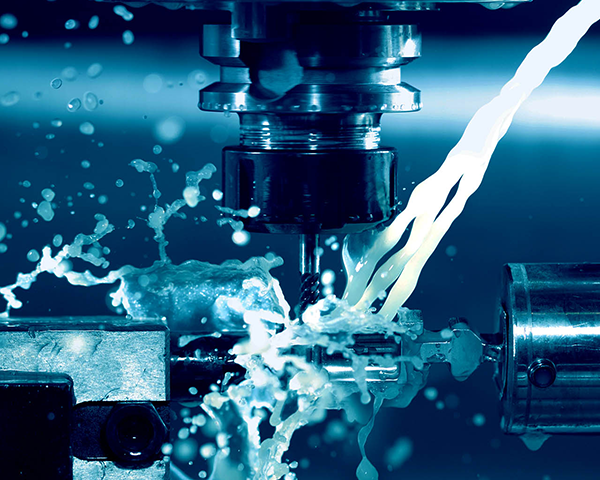

In 4-axis CNC milling, the fourth axis is added to the movement of the cutting tool, allowing it to rotate around the x-axis. Now, there are four axes: the x-axis, y-axis, z-axis, and a-axis (rotation around the x-axis). Most 4-axis CNC machines also allow the workpiece to rotate, which is called the b-axis, enabling the machine to function both as a milling machine and a lathe. If you need to drill holes on the side of a part or on the curved surface of a cylinder, 4-axis CNC machining is the perfect choice. It greatly speeds up the machining process and offers high machining precision.

4-axis machining is more advanced than 3-axis machining. Besides the tool moving on the XYZ plane, it also allows the workpiece to rotate on the Z-axis. This means that 4-axis milling can work on up to four faces without any special jigs or cutting tools. Additionally, 4-axis milling can improve the overall quality of precision part machining. Since the machine can machine on four faces with just one clamping, it can enhance the dimensional accuracy of parts.

Applications of Ripple MFG 4-Axis CNC Machining Services

4-axis CNC machining services are used in various industries because of their ability to produce complex and precise parts. Here are some major applications:

Automotive Industry

4-axis CNC machining services are used to manufacture various automotive parts, such as engine components, gears, and other complex parts requiring high precision.

Aerospace Industry

These machines are used to manufacture parts for airplanes and spacecraft, including turbine parts, wings, and other complex shapes that need precise machining from various angles.

Medical Industry

4-axis CNC machining services are used to manufacture medical devices and components, such as surgical instruments, orthopedic implants, and diagnostic equipment parts.

Electronics Industry

These machines are used to manufacture parts for electronic devices, such as circuit boards, connectors, and housings.

Woodworking

4-axis CNC machining services are used in woodworking to create complex designs and patterns on wooden parts.

Jewelry Industry

These machines produced by CNC machining services supplier are used to create complex designs and patterns on jewelry pieces.

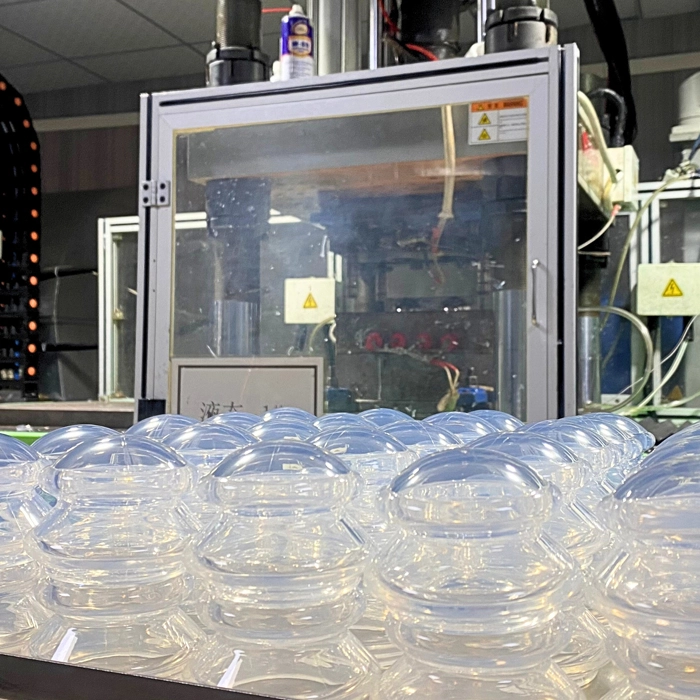

Mold Making

4-axis CNC machining services are used to make molds for various industries, including plastic injection molding and metal casting.

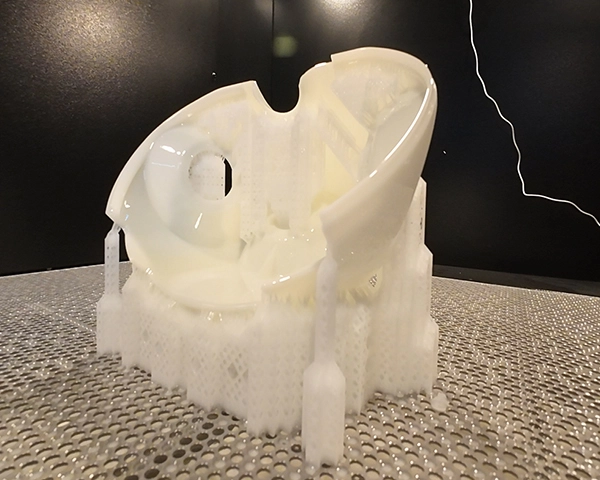

Prototyping

These machines are often used for prototyping because they can quickly and accurately produce complex parts from various materials.

Engraving

4-axis CNC machining services can be used to engrave complex patterns on various surfaces.

- Benefits of Custom Rapid Prototyping ServicesMarch 19, 2024In today's fast-moving industrial sector, custom rapid prototyping services have become an important tool for many companies to enhance the competitiveness of their products and accelerate the pac...view

- Custom Prototyping Services: The Key Bridge of Product DevelopmentJune 14, 2024In the journey of product development, prototyping occupies a crucial position. It is not only a bridge between design and actual manufacturing but also the first step in turning creativity into reali...view

- Customized Prototyping in Aerospace InnovationMarch 19, 2024In aerospace, every technological innovation and breakthrough marks a step into the unknown. Ripple MFG, as a leader in this field, has injected new vitality into the development of the aerospac...view

- Automotive Evolution: Enhancing Vehicle Design with Urethane Casting ServicesJanuary 5, 2024The world of automotive design has continuously evolved to meet the demands of consumers seeking high-performance vehicles. In recent years, urethane casting services have emerged as a vital tool for ...view

- What Is Pressure CastingFebruary 27, 2023Introduction to Pressure CastingPressure casting is a casting method in which molten or semi-molten metal is pressed into the metal casting mold at high speed and crystallized under pressure, referred...view

- Navigating the Nanoworld: High Precision Tools in Nanotechnology ApplicationsJanuary 5, 2024Welcome to the fascinating world of nanotechnology, where scientists and engineers manipulate matter at the tiniest scale. Unlocking the potential of this field requires the use of high precision tool...view