When using traditional steel molds for processing, due to the extremely thin material of the parts, the clearance between the punch and die must be sufficiently small, even close to zero-clearance punching, which demands high precision in mold design and manufacturing. Urethane, due to its high strength and excellent wear resistance, can withstand numerous repeated punchings by the punch, and its good flowability can meet the stamping process requirements of zero-clearance punching. Cast urethane services have been widely applied.

Differences Between Urethane Molds and Traditional Molds

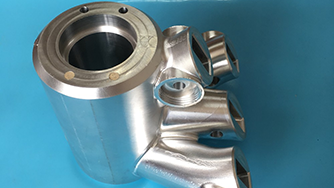

Cast urethane services provided by precision tooling supplier have introduced compression sleeves and use urethane instead of traditional steel dies. The role of the compression sleeve is to allow the urethane to be extruded into the gap of the chamfer of the sleeve when pressed by the punch, utilizing its high hardness to squeeze the raw material to the cutting edge of the punch, ensuring the material is sufficiently compressed to achieve a shearing effect. Physically, urethane is incompressible and has high hardness. When pressed, the urethane flows into the depth of the extrusion, creating pressure for punching.

Easy Separation

Using urethane instead of traditional steel dies in cast urethane services ensures that when compressed by the punch, the incompressible urethane flows into the gap between the compression sleeve and the die, fully compressing the material at the cutting edge to achieve the shearing effect. This process, theoretically, ensures zero-clearance punching, avoiding issues like improper separation of parts from raw materials and high burrs.

Lightweight and Highly Strong

Compared to traditional mold materials, urethane molds are characterized by being lightweight and highly strong. This means that for molds of the same size and shape, urethane molds are lighter, thus reducing transportation and installation costs. At the same time, the high strength of urethane molds ensures their stability and durability under high pressure and high temperature, reducing the risk of mold damage and further lowering production costs.

Good Machinability

Urethane molding has excellent machinability and can be quickly formed through processes such as injection molding and casting. This gives urethane molds higher flexibility and customizability in design and manufacturing. Cast urethane services can quickly adjust mold structures and sizes according to customer needs. Moreover, the short processing cycle in cast urethane services allows for quick delivery to customers, meeting market demands.

In summary, with its unique properties and wide range of applications, urethane has become an indispensable raw material in many industries. As a high-performance synthetic material, it boasts excellent wear resistance, impact resistance, chemical corrosion resistance, and good elasticity. High-quality raw materials are the cornerstone of manufacturing high-quality products. Ripple MFG's cast urethane services carefully select various raw materials to ensure the stable and reliable quality of the products, meeting your diverse needs.

- Prototype Machining Services: High-Efficiency Product OptimizationDecember 23, 2024What is Prototype Machining?Prototype machining is a manufacturing process used to create samples or prototypes of a product. It typically uses computer-aided design (CAD) software and computer numeri...view

- Sculpting the Future: 4 Axis CNC Machining Suppliers for Artistic CreationsNovember 23, 2023Art and technology converge in a symphony of precision, giving rise to a new era in creative expression. As artists push the boundaries of their craft, the collaboration with cutting-edge technology b...view

- The Future of Manufacturing: Urethane Casting Services in a Dynamic IndustryJanuary 5, 2024In the ever-evolving landscape of manufacturing, where precision, flexibility, and speed are paramount, the future is being shaped by innovative technologies like urethane casting services. This dynam...view

- A Guide to CNC Prototype ManufacturingSeptember 1, 2023What is CNC Prototype Manufacturing?CNC prototype manufacturing is a type of prototype manufacturing that uses Computer Numerical Control (CNC) machines to create physical prototypes of products. CNC ...view

- Food for Thought: Custom Prototyping in Culinary InnovationNovember 23, 2023Culinary innovation is an ever-evolving field that constantly seeks to push boundaries and tantalize our taste buds with new and exciting flavors. With the rise of the food and beverage industry, chef...view

- What Are the Applications of 4-Axis CNC Machining Services?September 14, 2024About 4-Axis CNC Machining ServicesIn 4-axis CNC milling, the fourth axis is added to the movement of the cutting tool, allowing it to rotate around the x-axis. Now, there are four axes: the x-axis, y...view

_20250123.webp)