With the increasingly fierce competition in the market, the speed and quality of product development have become the key factors for the success of enterprises. Among them, custom rapid prototyping plays an irreplaceable role as an important part of product development. In this paper, we will discuss the role of custom rapid prototyping in product development and introduce the unique brand advantages of Ripple MFG in Prototype, Rapid Tool and so on.

Rapidly verify the feasibility of product design

In the early stage of product development, custom rapid prototyping can help companies quickly verify the feasibility of product design. Through rapid prototyping, designers can create a model highly similar to the actual product in a short period of time, so as to test the function and appearance of the product. Ripple MFG's Prototype service, with its high efficiency and accuracy, provides designers with a reliable verification tool, which greatly shortens the product development cycle.

Reduce Product Development Costs and Risks

Through custom rapid prototyping, companies can identify potential problems and defects in the early stages of product development and make timely improvements and optimization. This avoids major errors in the later production process, thus reducing product development costs and risks. Ripple MFG, with its rich experience and expertise, is able to provide customers with high-quality rapid prototypes to ensure the smooth progress of product development.

Promote product innovation and personalization

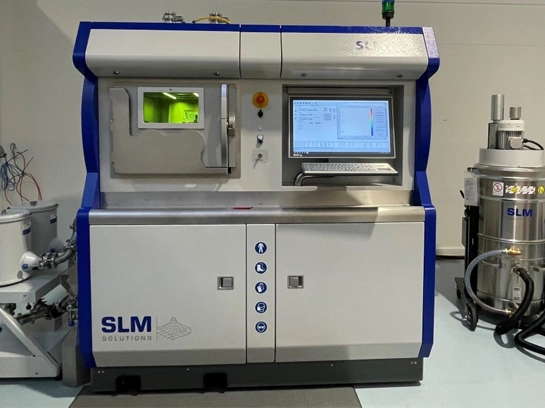

Custom rapid prototyping provides strong support for product innovation and personalized development. Designers can quickly try different design solutions and innovative ideas through customized rapid prototypes according to the market demand and customer feedback, and Ripple MFG's diversified manufacturing technologies, such as Plastic Molding, CNC Machining, 3D Print Vacuum Casting, etc., make customized rapid prototypes more flexible and versatile to meet product innovation. Ripple MFG's diverse manufacturing technologies, such as Plastic Molding, CNC Machining, 3D Print Vacuum Casting, etc., make the customized rapid prototypes more flexible and changeable, which meets the diversified needs of product innovation.

Improve market competitiveness

Through custom rapid prototyping, enterprises can bring their products to the market faster and seize the first opportunity. At the same time, high-quality rapid prototypes also set up a good brand image for the enterprise, improve market competitiveness, Ripple MFG with its excellent brand advantage and technical strength, to provide strong competitive support for the enterprise.

In summary, custom rapid prototyping plays a crucial role in product development. And Ripple MFG, with its unique brand advantage and technical strength, provides a strong guarantee for the realization of this goal.

- The Role of Cast Urethane Services in Automotive LightweightingJune 14, 2024With the development of various automobile companies, the competition in the automotive industry is becoming increasingly intense. Among all the competitive factors, cycle, quality, and cost are the t...view

- Timekeeping Triumphs: High Precision Tools in Watchmaking and HorologyJanuary 5, 2024In the intricate world of watchmaking and horology, where every tick of the clock is a testament to precision and craftsmanship, the role of high precision tools stands as the bedrock of excellence. T...view

- CNC Milling a Flame Retardant ABSJanuary 12, 2023CNC milling a flame retardant ABS, a strict tolerance of ±0.5° for all 4 inner corners.view

- Applications of Precise Tool and ManufacturingSeptember 14, 2024About Ripple MFG's Precision Toolings ServicesAccording to Ripple MFG's global service strategy, it is dedicated to providing precision plastic injection molding services including...view

- Prototype Machining Services: High-Efficiency Product OptimizationDecember 23, 2024What is Prototype Machining?Prototype machining is a manufacturing process used to create samples or prototypes of a product. It typically uses computer-aided design (CAD) software and computer numeri...view

- The Impact of Prototyping Machining Services in ArchitectureMarch 19, 2024With the advancement of science and technology, prototype machining services are increasingly used in the field of architecture, which has a profound impact on architectural design, construction and m...view