About Ripple MFG's Precision Toolings Services

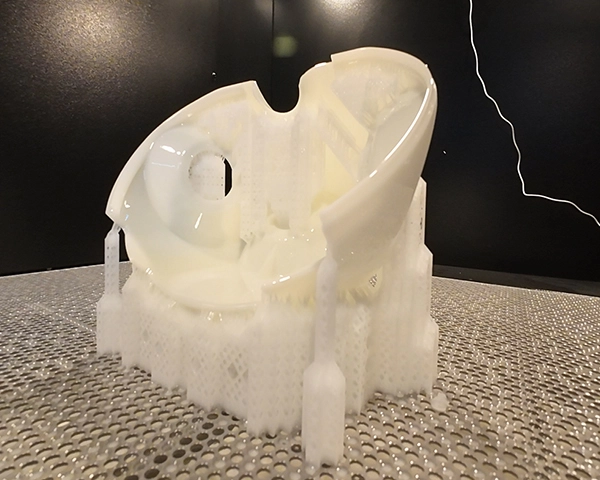

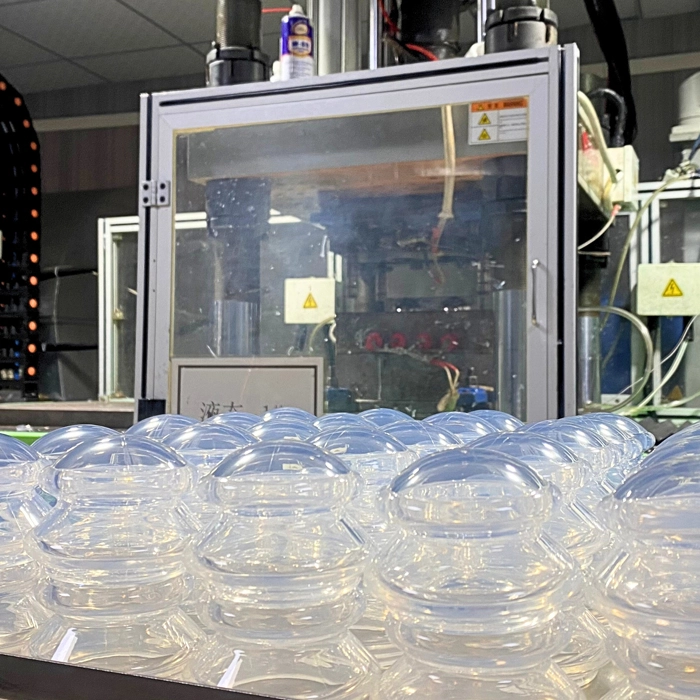

According to Ripple MFG's global service strategy, it is dedicated to providing precision plastic injection molding services including DFM project management, mold flow analysis, mold design, high-precision mold supply and manufacturing, mold trials, part manufacturing, quality inspection, and delivery. Ripple MFG is a precision injection molding manufacturer mainly offering mold services involving prototype molds, rapid molds, high-precision machining tools, and export molds, serving clients' various precision toolings processing and manufacturing plans. Prototype processing services and rapid mold services provide turnaround delivery times as fast as 7 days. Combined with Ripple MFG's injection molding services, for prototype projects and small batch needs, the fastest delivery time is 10 days.

Fields of Precise Tooling and Manufacturing Services

Precision tool making and manufacturing serves a wide range of industries, including but not limited to:

Automotive

Precision toolings are used to manufacture various automotive parts, including engine components, body parts, and interior components.

Aerospace

This industry requires high-precision toolings to produce airplane parts, including engines, structural components, and avionics.

Medical

Precision toolings are used to manufacture medical devices and instruments such as surgical tools, implants, and diagnostic equipment.

Electronics

Precision toolings are essential in the production of various electronic components and devices, including circuit boards, semiconductors, and sensors.

Defense

The defense industry relies on precision toolings to produce various military equipment and components, including weapons, vehicles, and protective gear.

Energy

By precision prototyping machining, precision toolings are used to manufacture components of various energy systems, including wind turbines, solar panels, and nuclear reactors.

Consumer Goods

Precision toolings are used to produce various consumer products, from appliances to toys to personal care products.

Construction

Precision toolings are used to manufacture various construction equipment and materials.

Telecommunications

Precision toolings are used to manufacture various telecommunication equipment, including network infrastructure and mobile devices.

Oil and Gas

Precision toolings are used to manufacture various equipment used in the oil and gas industry, including drilling equipment and pipeline components.

- Speeding Up Style: Custom Rapid Prototyping in Fashion DesignNovember 23, 2023Fashion is an ever-evolving industry that thrives on innovation and creativity. It is an art form that allows individuals to express their unique personalities and showcases the latest trends. In rece...view

- Advantages of Urethane Molds Compared to Traditional MoldsJune 14, 2024When using traditional steel molds for processing, due to the extremely thin material of the parts, the clearance between the punch and die must be sufficiently small, even close to zero-clearance pun...view

- Aerospace Advancements: Breaking Barriers with Precision Prototype MachiningJanuary 5, 2024As we continue to explore the boundless possibilities of space travel and aerospace engineering, one crucial element stands at the forefront of innovation – precision prototype machining. From pushin...view

- What Are the Applications of 4-Axis CNC Machining Services?September 14, 2024About 4-Axis CNC Machining ServicesIn 4-axis CNC milling, the fourth axis is added to the movement of the cutting tool, allowing it to rotate around the x-axis. Now, there are four axes: the x-axis, y...view

- The Role of Prototyping ServicesMarch 19, 2024Prototyping services play a pivotal role in modern manufacturing. It is not only a bridge between product design and production, but also a key force to promote product innovation and optimization. Fa...view

- Development History Of Injection MoldingFebruary 27, 2023Introduction to Injection Molding Injection molding is also known as injection molding, which is a kind of injection and molding method. The advantages of injection molding method are fast production ...view