In the construction industry, custom prototype manufacturing is a critical component to ensure a smooth project, and Ripple MFG stands out in the field of custom prototype manufacturing in construction with its superior technical capabilities and unique branding.

Prototyping: The bridge from design to physical reality

Designers' ideas need to be transformed into entities through prototyping, and Ripple MFG's Prototype service is the bridge for this transformation. Its efficient manufacturing process and exquisite skills ensure that the prototype can accurately display the design concept and provide valuable feedback for designers.

Rapid Tooling: Accelerating the Pace of Construction

Rapid tooling is the key to improving efficiency in construction, and Ripple MFG's Rapid Tool service can respond quickly to demand and provide high-quality construction tools, which provides strong support for accelerating the construction schedule and ensuring smooth project progress.

Diversified Manufacturing Technologies: Meeting Complex Challenges

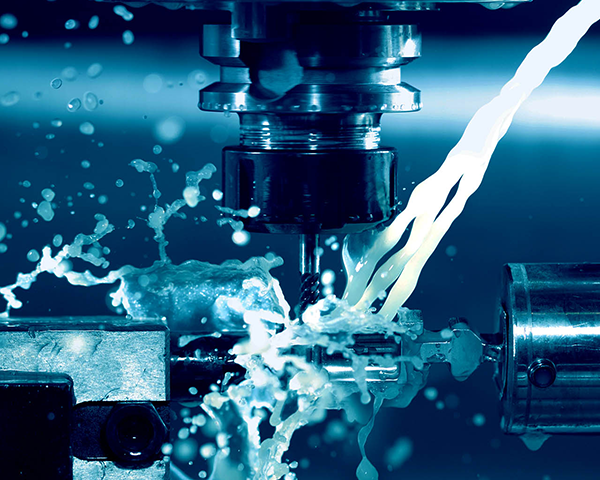

The manufacturing of architectural prototypes involves a variety of materials and processes, which requires manufacturers to have diversified technical strength. Ripple MFG has a deep technical background in the fields of Plastic Molding, CNC Machining, 3D Print Vacuum Casting, etc., which can cope with a variety of complex challenges and ensure the precision and quality of custom prototype manufacturing.

Customized Service: Meeting Individual Needs

With the continuous development of the construction industry, personalized needs are becoming more and more prominent, Ripple MFG provides customized services, prototyping according to the specific needs of customers, whether it is a unique architectural appearance or complex internal structure, can be accurately realized.

Quality Assurance: Setting the Industry Benchmark

At Ripple MFG, quality is an eternal pursuit. Whether it is prototyping, rapid tooling or customization services, we strictly follow high quality standards to ensure that every product meets customer expectations. This persistent pursuit of quality has enabled Ripple MFG to set an industry benchmark in the field of architectural custom prototype manufacturing.

In summary, Ripple MFG has demonstrated its strength in the field of architectural custom prototyping with the strength of its unique brand. Its superior technology, efficient processes and customized services have injected new vitality into the innovative development of the construction industry.

- Automotive Ingenuity: Revolutionizing Vehicle Design with Prototype MachiningJanuary 5, 2024In the modern automotive industry, innovation and technology play an integral role in shaping the future of vehicles. One process that stands out amidst this evolution is prototype machining. With its...view

- Which Is Used for Machining Small Parts?July 22, 2023Small Part Machining: What is it?Small part machining is a process that involves removing material from a workpiece to create a smaller and more intricate part. Small parts are often used in a wide ra...view

- The Role of Custom Rapid Prototyping in Product DevelopmentMarch 19, 2024With the increasingly fierce competition in the market, the speed and quality of product development have become the key factors for the success of enterprises. Among them, custom rapid prototyping pl...view

- The Impact of Prototyping Machining Services in ArchitectureMarch 19, 2024With the advancement of science and technology, prototype machining services are increasingly used in the field of architecture, which has a profound impact on architectural design, construction and m...view

- Automotive Evolution: Enhancing Vehicle Design with Urethane Casting ServicesJanuary 5, 2024The world of automotive design has continuously evolved to meet the demands of consumers seeking high-performance vehicles. In recent years, urethane casting services have emerged as a vital tool for ...view

- What Are the Process Steps for Cast Urethane Prototypes?September 14, 2024Polyurethane resin is a versatile material used to produce various plastic products. Its applications are diverse because it can produce both flexible, almost rubber-like products, and rigid plastics....view

_20250123.webp)