In the journey of product development, prototyping occupies a crucial position. It is not only a bridge between design and actual manufacturing but also the first step in turning creativity into reality. This article will explore the importance of custom precision prototyping services from multiple angles to reveal its key role in product design, production, and market application.

The Importance of Custom Prototyping

Custom prototyping services, in simple terms, involve making samples or models before mass production of the product. It enables designers and engineers to observe the strengths and weaknesses of the product design in reality, identify and fix problems promptly, thereby avoiding wasting substantial time, money, and manpower in future production processes. Through rapid prototyping, the team can verify the feasibility of the product, iteratively optimize the design, and conduct market testing and feedback in advance, ensuring that the final product meets user requirements.

Reducing Production Costs

With custom prototyping services, companies can comprehensively test product designs before mass production. This helps to identify and solve potential problems in time, reducing the defect rate in later production. In addition, custom prototyping services can assist companies in optimizing production processes and reducing production costs. By testing and improving the prototype multiple times before production, prototype manufacturing companies can ensure that the quality and performance of the final product meet expectations, thereby reducing production costs and market risks.

Prototyping Services

At Ripple MFG, we understand the value behind every idea. We are committed to providing our clients with precision prototypes that not only are easy to manufacture but genuinely meet their needs and expectations. Our custom prototyping services cover the entire process from initial design to final physical models, aiming to help clients better visualize their ideas and fully evaluate and iterate the product before mass production.

Why Choose Ripple MFG

Customer-Oriented: We always prioritize our clients' needs and are committed to offering tailored solutions to ensure the prototype not only reflects your creativity but also meets practical application needs.

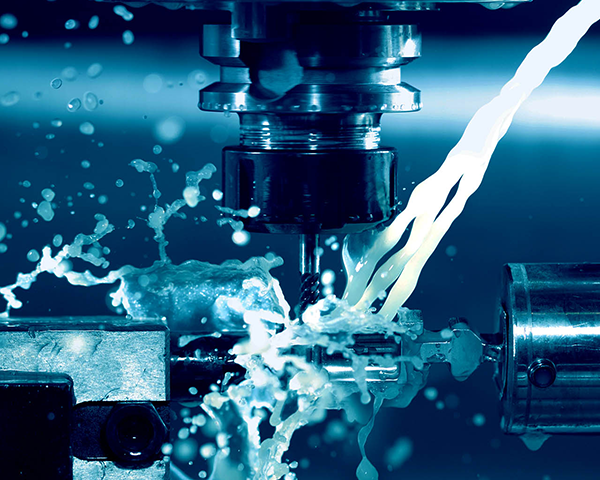

Technical Expertise: We utilize the most advanced manufacturing technologies and materials. From simple proof-of-concept models to complex functional prototypes, regardless of how complicated your requirements are, we can achieve them precisely.

Effective Communication: We believe that effective communication is key to successful prototyping. Our team works closely with you to ensure every detail meets your expectations, and promptly adjusts plans to meet your needs.

Whether you are a designer looking to validate a new product design or a company hoping to conduct market tests before mass production, Ripple MFG can provide professional custom prototyping services to help bring your ideas to life. We are not just manufacturers; we are partners in your innovation journey.

- What is the Tolerance of a 5 Axis CNC Machine?September 19, 2023What is 5 Axis CNC Machining?5 axis CNC machining is a type of computer-controlled machining that uses five axes of motion to cut and shape materials. The five axes allow for greater flexibility and p...view

- Sculpting the Future: 4 Axis CNC Machining Suppliers for Artistic CreationsNovember 23, 2023Art and technology converge in a symphony of precision, giving rise to a new era in creative expression. As artists push the boundaries of their craft, the collaboration with cutting-edge technology b...view

- Efficiency Redefined: The Impact of High Precision Tools in IndustriesJanuary 5, 2024In the ever-evolving landscape of industrial manufacturing, the pursuit of efficiency is paramount, and at the core of this quest lies the transformative impact of high precision tools. These sophisti...view

- Applications of Precise Tool and ManufacturingSeptember 14, 2024About Ripple MFG's Precision Toolings ServicesAccording to Ripple MFG's global service strategy, it is dedicated to providing precision plastic injection molding services including...view

- What Is Precision Injection Molding?December 23, 2024Precision injection molding refers to an injection molding method where the dimensional repeatability of the molded products is very high, making it difficult to achieve the required standards using g...view

- How Precision Tool Manufacturing Can Improve EfficiencyMarch 19, 2024In modern industrial manufacturing, precision tools play a vital role. With the intensification of market competition, improving the efficiency of precision tool manufacturing has become an urgent nee...view