As we continue to explore the boundless possibilities of space travel and aerospace engineering, one crucial element stands at the forefront of innovation – precision prototype machining. From pushing the boundaries of exploration to revolutionizing aircraft design, prototype machining is an indispensable tool in the aerospace industry. In this blog post, we will examine the significance of prototype machining and its role in shaping the future of aerospace advancements.

The Importance of Prototype Machining in Aerospace Engineering

Prototype machining plays a vital role in aerospace engineering, enabling engineers and designers to transform groundbreaking ideas into tangible reality. By producing accurate and functional prototypes, aerospace companies can thoroughly test and refine their designs, saving both time and resources in the long run. Whether it's developing new rocket engines, advanced avionics systems, or novel aircraft designs, prototype machining facilitates the optimization of these concepts and ensures their feasibility before moving forward with full-scale production.

Advancements in Precision Prototype Machining Technology

With the rapid advancement of precision prototype machining technology, aerospace engineers now have access to unparalleled design capabilities. Computer Numerical Control (CNC) machines have revolutionized the industry, allowing for intricate and complex designs to be transformed into high-quality prototypes with exceptional accuracy. These machines, coupled with advanced software simulation tools, enable engineers to create prototypes that are not only visually impressive but also functional in mimicking actual conditions and performance.

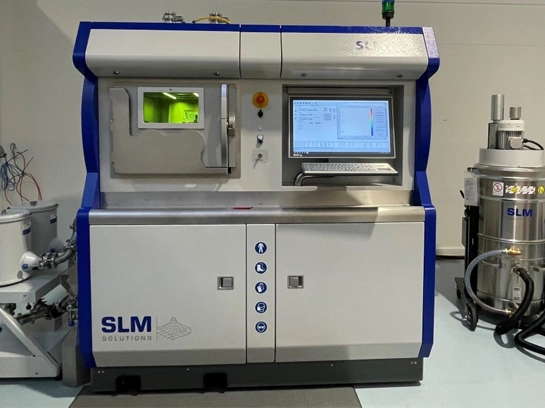

Moreover, 3D printing has emerged as a game-changer in the field of prototype machining. It offers a cost-effective and time-efficient approach to create intricate parts that were once deemed challenging to manufacture. Whether it's intricate fuel nozzles or customized brackets, additive manufacturing has empowered aerospace engineers to explore new frontiers by pushing the limits of design and material possibilities.

Accelerating Aerospace Innovations with Prototype Machining

The aerospace industry is driven by innovation and pushing boundaries. Prototype machining acts as the catalyst for these advancements, enabling engineers to unlock new possibilities and redefine traditional norms. By embracing the iterative nature of prototype machining, engineers can quickly identify design flaws, make necessary adjustments, and continuously improve upon their concepts, ultimately leading to safer and more efficient aircraft and space vehicles.

Moreover, aerospace companies are no longer limited to merely replicating existing designs. Prototype machining allows them to take risks and test unconventional ideas that have the potential to transform the industry. From cutting-edge propulsion systems to revolutionary aerodynamic designs, prototype machining empowers engineers to think outside the box and embrace creative solutions that were once deemed impossible.

In the fast-paced world of aerospace engineering, precision prototype machining plays an indispensable role in pushing the boundaries of innovation and revolutionizing the way we explore space. By leveraging the power of advanced technologies such as CNC machines and 3D printing, aerospace engineers can transform their visions into reality, allowing for continuous improvement and optimization of their designs. As we move forward, it is clear that prototype machining will continue to be a driving force behind aerospace advancements, shaping a future where the impossible becomes possible.

- Optimize Product Development Cycle with Custom Prototyping ServicesJune 14, 2024Molds are indispensable basic technological equipment in the manufacturing industry, primarily used for efficient mass production of various industrial product components and parts. They are widely ap...view

- Small Parts, Big Impact: Precision Prototyping Machining in Micro ManufacturingOctober 27, 2023In the realm of manufacturing, precision is the name of the game. Nowhere is this more evident than in micro manufacturing, where the creation of tiny, intricate components is crucial for a wide range...view

- Timekeeping Triumphs: High Precision Tools in Watchmaking and HorologyJanuary 5, 2024In the intricate world of watchmaking and horology, where every tick of the clock is a testament to precision and craftsmanship, the role of high precision tools stands as the bedrock of excellence. T...view

- What is the Tolerance of a 5 Axis CNC Machine?September 19, 2023What is 5 Axis CNC Machining?5 axis CNC machining is a type of computer-controlled machining that uses five axes of motion to cut and shape materials. The five axes allow for greater flexibility and p...view

- Development History Of Injection MoldingFebruary 27, 2023Introduction to Injection Molding Injection molding is also known as injection molding, which is a kind of injection and molding method. The advantages of injection molding method are fast production ...view

- What Are the Process Steps for Cast Urethane Prototypes?September 14, 2024Polyurethane resin is a versatile material used to produce various plastic products. Its applications are diverse because it can produce both flexible, almost rubber-like products, and rigid plastics....view