What is CNC Prototype Manufacturing?

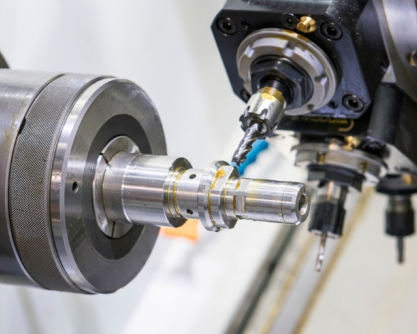

CNC prototype manufacturing is a type of prototype manufacturing that uses Computer Numerical Control (CNC) machines to create physical prototypes of products. CNC machines use a computer-controlled system to move cutting tools and other machinery to create precise and complex shapes from a variety of materials, including plastics, metals, and composites. CNC prototype manufacturing is a highly precise and efficient process that can create accurate and consistent prototypes quickly.

CNC custom prototype manufacturing is commonly used in the automotive, aerospace, and medical industries, where precise and complex parts are required. It is also used in the consumer goods industry, where it is used to create product prototypes and molds.

Advantages of CNC Prototype Manufacturing

There are several advantages to using CNC prototype manufacturing in the product development process.

Precise and Consistent Results

One of the biggest advantages of CNC prototype manufacturing is that it can create highly precise and consistent results. CNC machines use computer-controlled systems to move cutting tools and other machinery, which means that they can create highly accurate and complex shapes. This precision and consistency can help to ensure that the final product meets the required standards.

Fast Turnaround Time

CNC prototype manufacturing is a highly efficient process that can create accurate and consistent prototypes quickly. This means that prototype manufacturing companies can create prototypes faster and get products to market quicker. The fast turnaround time can be especially important in competitive industries, where time to market can be crucial.

Cost Savings

CNC prototype manufacturing can also help to save costs in the product development process. By creating highly precise and accurate prototypes, manufacturers can avoid costly mistakes down the line. CNC machines can also work with a variety of materials, which can help to reduce material costs. Additionally, the fast turnaround time can help to reduce labor costs and overall production costs.

Versatility

CNC machines can work with a variety of materials, including plastics, metals, and composites. This versatility can be especially important in industries where a wide range of materials are used. CNC machines can also create a variety of shapes and sizes, which means that they can be used to create complex and unique parts.

Automation

CNC machines are highly automated, which means that they require less manual labor than other types of prototype manufacturing. This can help to reduce labor costs and improve overall efficiency. Additionally, the automation can help to ensure consistent results, which can be important in industries where precision is crucial.

CNC prototype manufacturing is a highly precise and efficient process that can create accurate and consistent prototypes quickly. It is commonly used in industries where precise and complex parts are required, including the automotive, aerospace, and medical industries. There are several advantages to using CNC prototype manufacturing in the product development process, including precise and consistent results, fast turnaround time, cost savings, versatility, and automation. By using CNC prototype manufacturing, manufacturers can create prototypes quickly, reduce costs, and ensure that the final product meets the required standards.

- Aerospace Advancements: Breaking Barriers with Precision Prototype MachiningJanuary 5, 2024As we continue to explore the boundless possibilities of space travel and aerospace engineering, one crucial element stands at the forefront of innovation – precision prototype machining. From pushin...view

- Medical Marvels: Urethane Casting for Prosthetics and OrthopedicsNovember 23, 2023In the ever-evolving world of medical technology, new advancements are constantly being made to improve the lives of patients. One such innovation that has revolutionized the field of prosthetics and ...view

- Speeding Up Style: Custom Rapid Prototyping in Fashion DesignNovember 23, 2023Fashion is an ever-evolving industry that thrives on innovation and creativity. It is an art form that allows individuals to express their unique personalities and showcases the latest trends. In rece...view

- Prototype Machining Services: High-Efficiency Product OptimizationDecember 23, 2024What is Prototype Machining?Prototype machining is a manufacturing process used to create samples or prototypes of a product. It typically uses computer-aided design (CAD) software and computer numeri...view

- Exploring the Capabilities of 5 Axis CNC MachiningSeptember 1, 20235 axis CNC machining is a type of computer-controlled machining that utilizes five axes of motion to cut and shape materials. It is an advanced and versatile manufacturing process that is capable of p...view

- Automotive Ingenuity: Revolutionizing Vehicle Design with Prototype MachiningJanuary 5, 2024In the modern automotive industry, innovation and technology play an integral role in shaping the future of vehicles. One process that stands out amidst this evolution is prototype machining. With its...view

_20250123.webp)