With the development of various automobile companies, the competition in the automotive industry is becoming increasingly intense. Among all the competitive factors, cycle, quality, and cost are the three core elements of competition in the automotive industry. Shortening project cycles, improving the quality of the entire vehicle, and reducing development costs are common goals for all automotive companies. Casting urethane services provide new solutions for automobile manufacturers.

Shortcomings of Traditional Processes

Currently, the material of the pressure plates for stamping dies is all metal, and mold manufacturers use fitting methods to ensure the coloring rate of the pressure surface. However, metal pressure plates have the disadvantages of high processing costs, high work intensity, and long fitting cycles. At the same time, metal pressure plates affect the size and surface quality of the parts. As precision prototyping and manufacturing manufacturers increasingly demand lower costs, higher quality, and shorter cycles, metal pressure plates are increasingly unable to meet the needs of current projects.

Lightweight Characteristics

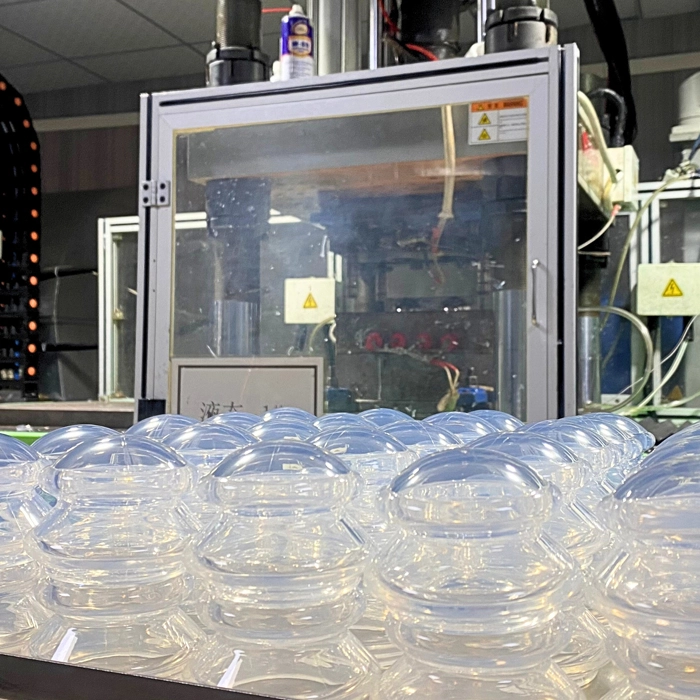

Urethane is a lightweight and high-performance polymer material that has excellent elasticity, wear resistance, corrosion resistance, and oil resistance. These characteristics make urethane an ideal choice for automotive lightweight materials. In multiple automobile components, such as steering wheels, seats, and interiors, cast urethane services have been widely used, effectively reducing the overall weight of the vehicle.

Application in Vehicle Body Structure

In the automotive body structure, urethane materials are mainly used to make various interior and exterior parts. For example, using urethane foam materials to make dashboards, seats, and steering wheels not only reduces weight but also provides good comfort and safety. In addition, urethane can also be used as a filling material for body panels, engine hoods, and other components to effectively reduce the overall weight of the vehicle.

Application in Chassis Systems

The chassis system is an important part of an automobile and has a crucial impact on the vehicle's performance and safety. In the chassis system, casting urethane services are mainly used to make suspension systems, shock absorbers, and other components. These parts, made of urethane material, are not only lightweight but also have good shock absorption effects and durability, improving the comfort and safety of driving.

As lightweight becomes the main trend in the future development of the automotive field, the effective use of polymer materials is necessary. This not only realizes the lightweight of automobiles but also has certain energy-saving and environmental protection effects. Casting urethane services can make automotive manufacturing more complete and enhance the overall performance of vehicles. In the structure and decoration of automotive manufacturing, casting urethane services can be reasonably utilized.

- Prototype Machining Services: High-Efficiency Product OptimizationDecember 23, 2024What is Prototype Machining?Prototype machining is a manufacturing process used to create samples or prototypes of a product. It typically uses computer-aided design (CAD) software and computer numeri...view

- The Future of Manufacturing: Urethane Casting Services in a Dynamic IndustryJanuary 5, 2024In the ever-evolving landscape of manufacturing, where precision, flexibility, and speed are paramount, the future is being shaped by innovative technologies like urethane casting services. This dynam...view

- How Is Prototyping Used in the Automotive Industry?July 22, 2023Automotive rapid prototyping is an essential process used in the automotive industry to develop new vehicles and components. Prototyping allows designers and engineers to test and refine their ideas b...view

- What Are the Process Steps for Cast Urethane Prototypes?September 14, 2024Polyurethane resin is a versatile material used to produce various plastic products. Its applications are diverse because it can produce both flexible, almost rubber-like products, and rigid plastics....view

- What Are the Applications of 4-Axis CNC Machining Services?September 14, 2024About 4-Axis CNC Machining ServicesIn 4-axis CNC milling, the fourth axis is added to the movement of the cutting tool, allowing it to rotate around the x-axis. Now, there are four axes: the x-axis, y...view

- Benefits of Custom Rapid Prototyping ServicesMarch 19, 2024In today's fast-moving industrial sector, custom rapid prototyping services have become an important tool for many companies to enhance the competitiveness of their products and accelerate the pac...view