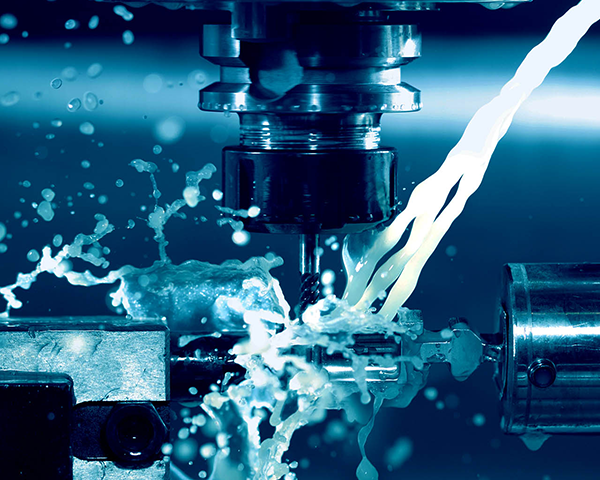

First, precision CNC machining process is concentrated

CNC machine tools generally with automatic tool changer, tool magazine, tool change process automatically controlled by the program, therefore, the process is more concentrated. Process concentration brings great economic benefits, including reducing the machine tool footprint, saving plant and reduce or no intermediate links (such as intermediate testing of semi-finished products, temporary storage and handling, etc.), saving time and manpower.

Second, precision CNC machining automation

Precision CNC machining, no manual control of the tool, a high degree of automation.

1, the requirements of the operator to reduce: an ordinary machine tool senior workers, not a short time can be trained, and a CNC worker without programming training time is extremely short. And, CNC workers on CNC machine tools to process the parts than ordinary workers on traditional machine tools to process the parts of high precision, time to save.

2, reduce the labor intensity of workers: CNC workers in the processing process, most of the time is excluded from the processing process, very labor-saving.

3, product quality and stability: CNC high precision tools processing automation, eliminating the fatigue of workers on ordinary machine tools, carelessness, estimation and other human errors, to improve the consistency of the product.

4, high processing efficiency: CNC machine tools such as automatic tool change makes the processing process compact, improving labor productivity.

Third, precision CNC machining to adapt to market competition

Precision CNC machining services as long as you change the program, you can process new parts on the CNC machine tool, and can automate the operation, good flexibility, high efficiency, so the CNC machine tool can well adapt to market competition.

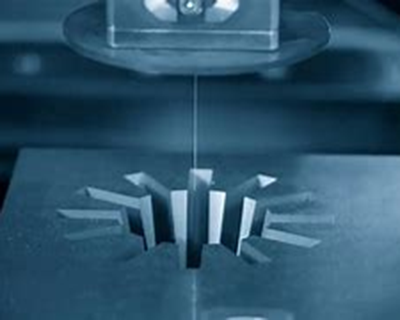

Fourth, precision CNC machining capability

Machine tools can accurately process a variety of contours, and some contours in ordinary machine tools can not be processed. CNC machine tools are particularly suitable for the following occasions: no scrap parts, new product development and urgent parts of the processing.

Precision CNC machining than traditional machine tool processing has changed a lot, the efficiency is also greatly improved, which is also the benefit of the continuous development of science and technology.

- Innovation Unleashed: the Role of Prototype Machining in Product DevelopmentJanuary 5, 2024In the dynamic realm of product development, where ideas evolve into tangible innovations, the role of prototype machining stands as a cornerstone for success. The journey from concept to market-ready...view

- Which Is Used for Machining Small Parts?July 22, 2023Small Part Machining: What is it?Small part machining is a process that involves removing material from a workpiece to create a smaller and more intricate part. Small parts are often used in a wide ra...view

- Gaming Gadgets Galore: How Urethane Casting Services Shape Interactive ExperiencesJanuary 5, 2024In the dynamic world of gaming, where innovation and immersive experiences are driving forces, the role of urethane casting services emerges as a crucial element in the development of cutting-edge gam...view

- Precise Tool and Manufacturing Technology: The Precise Force Driving Industrial ProgressSeptember 18, 2024The Importance of Precise Tool and Manufacturing TechnologyIn modern industry, the application of precise tool and manufacturing is becoming increasingly widespread. They are not only a symbol of tech...view

- The Role of Cast Urethane Services in Automotive LightweightingJune 14, 2024With the development of various automobile companies, the competition in the automotive industry is becoming increasingly intense. Among all the competitive factors, cycle, quality, and cost are the t...view

- The Role of Prototyping ServicesMarch 19, 2024Prototyping services play a pivotal role in modern manufacturing. It is not only a bridge between product design and production, but also a key force to promote product innovation and optimization. Fa...view