When it comes to crafting musical instruments, precision and attention to detail are paramount. Whether it's a finely tuned guitar, a melodically rich piano, or a beautifully crafted violin, every note produced by these instruments must resonate in harmony with the musician's soul. This is where 4 Axis CNC Machining plays a vital role for musical instrument suppliers, enabling them to bring the perfect note to life through flawless precision and versatility.

The Perfect Note: The Role of 4 Axis CNC Machining in Crafting Musical Instruments

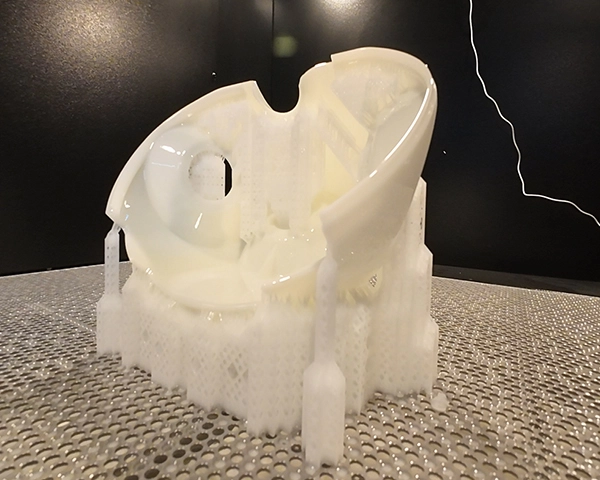

Musical instrument suppliers understand the fundamental importance of precision in their craft. With 4 Axis CNC Machining, suppliers can achieve exceptional accuracy like never before. This sophisticated technology enables the crafting of intricate components that ensure flawless sound quality and superior performance. From precise fretboard inlays to intricately shaped guitar bodies, 4 Axis CNC Machining empowers suppliers to create instruments that musicians will truly cherish.

Precision and Versatility: The Benefits of 4 Axis CNC Machining

4 Axis CNC Machining services bring a wide range of benefits to the table for musical instrument suppliers. One key advantage is the ability to produce complex shapes and contours that were previously unattainable. By utilizing advanced software and machinery, suppliers can create intricately designed instrument components with utmost precision. This flexibility in design and manufacturing reduces waste and opens up a world of creative possibilities, all while ensuring optimal functionality and sound quality.

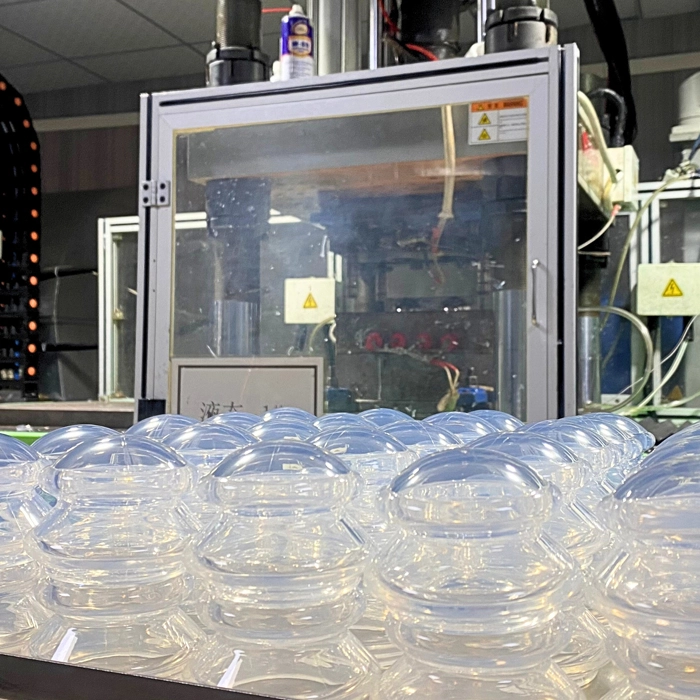

Additionally, 4 Axis CNC Machining allows for faster production times and improved efficiency. This technology facilitates simultaneous machining on multiple axes, enabling suppliers to handle various elements of instrument production simultaneously. With reduced manual labor and improved automation, musical instrument suppliers can meet increasing demand without compromising on quality or delivery timelines.

Empowering Musical Instrument Suppliers with 4 Axis CNC Machining

As technology continues to advance, it is crucial for musical instrument suppliers to embrace the benefits offered by 4 Axis CNC Machining. By investing in this cutting-edge technology, suppliers can enhance their competitiveness in the market. Not only does the precision and versatility of 4 Axis CNC Machining allow suppliers to create high-quality instruments, but it also enables them to differentiate themselves from their competitors.

Furthermore, as one of the common custom prototyping services, 4 Axis CNC Machining empowers suppliers to provide customization options to musicians. By leveraging this technology, suppliers can offer personalized instrument designs, whether it's individualized engravings or unique contours tailored to the musician's preferences. This level of customization fosters a deeper connection between the musician and their instrument, reinforcing the idea that every musical journey is unique.

Keeping the Rhythm Alive: Enhancing Production Efficiency with 4 Axis CNC Machining

In order to keep the rhythm alive and supply instruments to a wider audience, musical instrument suppliers must prioritize efficiency. 4 Axis CNC Machining provided by a prototype manufacturing company offers a solution to streamline production processes. With faster machining times and reduced error rates, this technology significantly improves overall production efficiency. By optimizing manufacturing processes, suppliers can maximize output without compromising on quality, ultimately meeting the ever-growing demand for musical instruments.

4 Axis CNC Machining brings harmony to the world of musical instrument suppliers. By harnessing the benefits of precision, versatility, and enhanced production efficiency, suppliers can create instruments that truly resonate with musicians. This technology not only helps suppliers craft the perfect note but also empowers them to meet the evolving needs and desires of today's musicians, ensuring that the rhythm of creativity and musical expression continues to thrive.

- Food for Thought: Custom Prototyping in Culinary InnovationNovember 23, 2023Culinary innovation is an ever-evolving field that constantly seeks to push boundaries and tantalize our taste buds with new and exciting flavors. With the rise of the food and beverage industry, chef...view

- Automotive Ingenuity: Revolutionizing Vehicle Design with Prototype MachiningJanuary 5, 2024In the modern automotive industry, innovation and technology play an integral role in shaping the future of vehicles. One process that stands out amidst this evolution is prototype machining. With its...view

- A Guide to CNC Prototype ManufacturingSeptember 1, 2023What is CNC Prototype Manufacturing?CNC prototype manufacturing is a type of prototype manufacturing that uses Computer Numerical Control (CNC) machines to create physical prototypes of products. CNC ...view

- What Are The Characteristics Of Precision CNC MachiningFebruary 27, 2023First, precision CNC machining process is concentratedCNC machine tools generally with automatic tool changer, tool magazine, tool change process automatically controlled by the program, therefore, th...view

- Which Is Used for Machining Small Parts?July 22, 2023Small Part Machining: What is it?Small part machining is a process that involves removing material from a workpiece to create a smaller and more intricate part. Small parts are often used in a wide ra...view

- Benefits of Custom Rapid Prototyping ServicesMarch 19, 2024In today's fast-moving industrial sector, custom rapid prototyping services have become an important tool for many companies to enhance the competitiveness of their products and accelerate the pac...view