What is Vacuum Casting

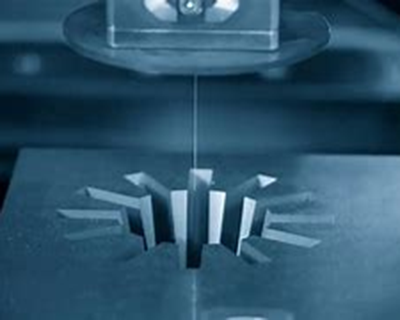

Vacuum casting is a manufacturing process used to create high-quality, detailed, and dimensionally accurate replicas or prototypes of original models. It involves the use of a vacuum to draw liquid material into a mold, which then hardens to form the desired part. This process is often used in industries such as automotive, aerospace, medical, and consumer products for rapid prototyping machining services and low-volume production.

Why Vacuum Casting

In our daily lives, we often apply plastic products, in general products, that use more thermoplastics, this plastic in industrial production, generally with thermoforming, can be shaped. However, in our product design, the appearance of some products needs to be heat and corrosion-resistant, these products need to use plastic and should have good thermosetting, the designer in the selection of materials, we to take into account the way the product is formed will be used in the vacuum casting process.

Vacuum Casting Mainly Usage

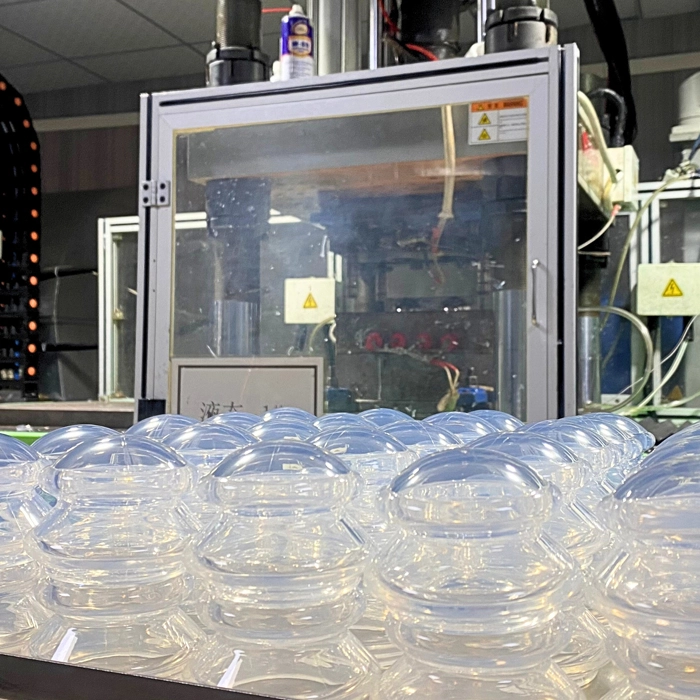

Vacuum casting is mainly used for prototype manufacturing, single-piece production, and small-batch production, and can replicate almost all the properties of the injection molding process. It is mainly used to mold two-component polyurethanes (PUR), which are widely used in different grades, colors, and hardnesses. Flexible silicone molds are machined directly from the mold and then vacuum cast to reproduce the product with properties very similar to those of mass-produced products. A full-color range is available. Can be as flexible and elastic as a thermoplastic elastomer (TPE) or as hard as acrylonitrile-butadiene-styrene (ABS).

Typical Applications for Vacuum Casting

Vacuum casting is widely used in the automotive, consumer electronics, consumer goods, and sports equipment industries. In addition to prototypes, vacuum casting is also used for injection molding of small quantities where expensive molds are not intended. In the automotive industry, applications include the production of various tubes, water tanks, air filter housings, radiator parts, lamp shades, chips, gears, and moving hinges. Consumer electronics applications include the manufacture of keyboards and housings for cell phones, televisions, cameras, players, audio systems, and computers.

- Urethane Casting for Custom Parts: Your Key to InnovationOctober 27, 2023Innovation is the lifeblood of progress in product development, and for those seeking to create custom parts with precision and flexibility, urethane casting services are emerging as a pivotal solutio...view

- Medical Marvels: Innovations in Prototype Machining for Healthcare DevicesJanuary 5, 2024In today's rapidly advancing world, innovation in the healthcare sector has become essential for better patient outcomes. One area that has seen remarkable progress is prototype machining for heal...view

- Automotive Ingenuity: Revolutionizing Vehicle Design with Prototype MachiningJanuary 5, 2024In the modern automotive industry, innovation and technology play an integral role in shaping the future of vehicles. One process that stands out amidst this evolution is prototype machining. With its...view

- How Is Prototyping Used in the Automotive Industry?July 22, 2023Automotive rapid prototyping is an essential process used in the automotive industry to develop new vehicles and components. Prototyping allows designers and engineers to test and refine their ideas b...view

- Aerospace Advancements: Breaking Barriers with Precision Prototype MachiningJanuary 5, 2024As we continue to explore the boundless possibilities of space travel and aerospace engineering, one crucial element stands at the forefront of innovation – precision prototype machining. From pushin...view

- Medical Marvels: Urethane Casting for Prosthetics and OrthopedicsNovember 23, 2023In the ever-evolving world of medical technology, new advancements are constantly being made to improve the lives of patients. One such innovation that has revolutionized the field of prosthetics and ...view