Precision injection molding refers to an injection molding method where the dimensional repeatability of the molded products is very high, making it difficult to achieve the required standards using general injection molding machines and conventional injection molding processes. The concept of "precision injection molding" is primarily distinguished from "conventional injection molding." It is based on the rapid development of polymer materials, where precision plastic components are used to replace high-precision metal parts in the fields of instrumentation and electronics.

Currently, there are two criteria for defining precision injection molded products:

One is the dimensional repeatability of the product; the second is the mass repeatability of the product.

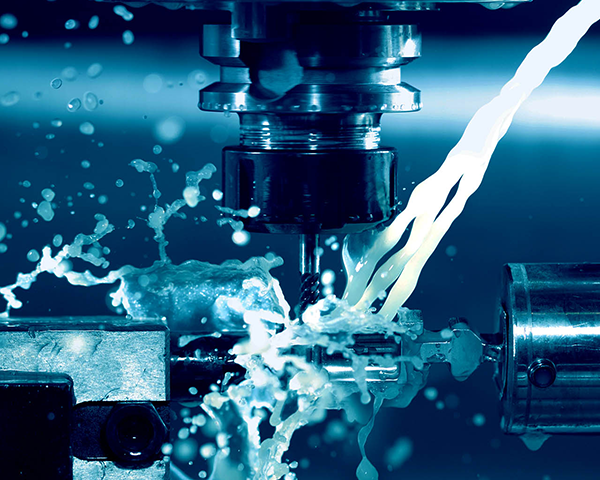

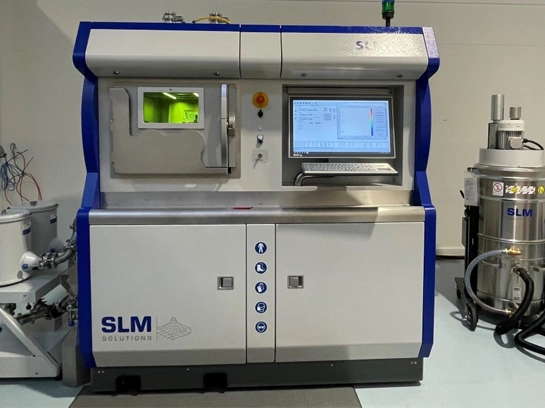

The mold for the molded products is an important condition that determines whether the product can meet the design requirements for dimensional tolerance. As a common type of prototyping machining services, the precision injection molding machine is key equipment that ensures the product is always molded within the required dimensional tolerance range, guaranteeing a very high yield rate.

Characteristics of precision injection molding

High dimensional accuracy and small tolerances of the parts, meaning high precision in size limits;

High repeatability in product weight, requiring dimensional stability over days, months, and years;

Good material and sufficient rigidity of the mold, with high precision in cavity dimensions, surface finish, and high positioning accuracy between templates;

Using precision injection molding machines to replace conventional injection molding machines;

Applying precision injection molding processes;

Selecting materials suitable for precision injection molding.

The most important technical indicators for evaluating products are the precision of injection molded products (dimensional tolerance, form and position tolerance, and surface finish).

Requirements for precision injection molding

Precision plastic injection molding machines typically require product dimensional accuracy to be within 0.01 to 0.001 mm. Many precision injection moldings also require the injection machine to have high injection pressure and high injection speed;

The molding system is required to have sufficient rigidity and high clamping precision. Clamping precision refers to the uniformity, adjustability, stability, and high repeatability of the clamping force, as well as high positional accuracy for opening and closing the mold;

There is a requirement for precise control over pressure, flow, temperature, and measurement to the corresponding precision. Adopting multistage or stepless injection ensures the reproducibility of molding processes and the repeatability of product dimensions.

As an experienced precision injection molding manufacturer, Ripple MFG focuses on the injection molding, insert molding, and overmolding of various plastic products in different industries such as the automotive and medical industries. With advanced capabilities and an in-depth understanding of precision prototype design and manufacturing, we provide solutions that meet manufacturing needs. From prototype manufacturing to high-volume production, our state-of-the-art equipment and facilities enable us to flexibly and quickly deliver high-quality molded products.

- What Are the Applications of 4-Axis CNC Machining Services?September 14, 2024About 4-Axis CNC Machining ServicesIn 4-axis CNC milling, the fourth axis is added to the movement of the cutting tool, allowing it to rotate around the x-axis. Now, there are four axes: the x-axis, y...view

- What Are the Process Steps for Cast Urethane Prototypes?September 14, 2024Polyurethane resin is a versatile material used to produce various plastic products. Its applications are diverse because it can produce both flexible, almost rubber-like products, and rigid plastics....view

- Applications of Precise Tool and ManufacturingSeptember 14, 2024About Ripple MFG's Precision Toolings ServicesAccording to Ripple MFG's global service strategy, it is dedicated to providing precision plastic injection molding services including...view

- The Role of Cast Urethane Services in Automotive LightweightingJune 14, 2024With the development of various automobile companies, the competition in the automotive industry is becoming increasingly intense. Among all the competitive factors, cycle, quality, and cost are the t...view

- Precise Tool and Manufacturing Technology: The Precise Force Driving Industrial ProgressSeptember 18, 2024The Importance of Precise Tool and Manufacturing TechnologyIn modern industry, the application of precise tool and manufacturing is becoming increasingly widespread. They are not only a symbol of tech...view

- Speeding Up Style: Custom Rapid Prototyping in Fashion DesignNovember 23, 2023Fashion is an ever-evolving industry that thrives on innovation and creativity. It is an art form that allows individuals to express their unique personalities and showcases the latest trends. In rece...view