In the modern automotive industry, innovation and technology play an integral role in shaping the future of vehicles. One process that stands out amidst this evolution is prototype machining. With its ability to bring ideas to life, prototype machining is revolutionizing vehicle design, enabling manufacturers to push boundaries and create groundbreaking concepts. In this blog post, we will explore how prototype machining has become a game-changer in the automotive industry, highlighting its significance in the process of designing and manufacturing vehicles.

A Game-Changer in Automotive Industry Evolution

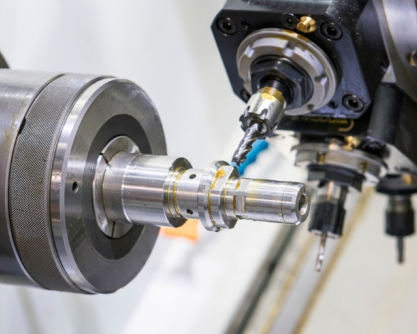

The traditional approach to vehicle design followed a time-consuming and costly route, involving manual mold making and subsequent testing. However, thanks to the advent of prototype machining, manufacturers now have a faster and more efficient alternative. By utilizing computer-aided design (CAD) and computer-aided manufacturing (CAM) technologies, engineers can create a virtual blueprint of a vehicle component or design concept. From there, a rapid prototype can be produced, allowing for thorough testing and evaluation.

Prototype machining accelerates the overall design process, reducing time and resources required for multiple iterations of product development. This streamlined approach brings tremendous benefits to the automotive industry, enabling manufacturers to optimize their designs and reduce the time it takes for vehicles to reach the market.

The Power of Prototype Machining in Vehicle Design and Manufacturing

Prototype machining is an essential tool for automotive design and manufacturing, as it allows manufacturers to verify their concepts with real-life samples. By creating physical prototypes, engineers can perform in-depth testing, evaluating the functional aspects, durability, and overall performance of the vehicle components. Any required modifications or improvements can be identified and implemented efficiently, greatly minimizing the risks and costs associated with design flaws.

Additionally, prototype machining opens up avenues for innovation and creativity. By swiftly bringing design ideas to reality, manufacturers can explore novel concepts and experiment with unconventional features. This freedom to innovate gives birth to groundbreaking automotive designs that captivate the market and propel the industry forward.

Moreover, prototype machining plays a pivotal role in the manufacturing process. It allows manufacturers to test the feasibility of mass production, assess manufacturing tolerances, and fine-tune assembly processes. This ensures that once the final design is approved, the vehicle can be produced efficiently, meeting the highest quality standards.

In conclusion, prototype machining is redefining vehicle design and manufacturing in the automotive industry. With its ability to accelerate the design process and enable rapid testing and evaluation, it ensures that innovative concepts become a reality. By embracing prototype machining, manufacturers can push boundaries, optimize designs, and create vehicles that captivate the market. As the automotive industry continues to evolve, prototype machining plays a crucial role in shaping the future of vehicle design and technology.

- Efficiency Redefined: The Impact of High Precision Tools in IndustriesJanuary 5, 2024In the ever-evolving landscape of industrial manufacturing, the pursuit of efficiency is paramount, and at the core of this quest lies the transformative impact of high precision tools. These sophisti...view

- Development History Of Injection MoldingFebruary 27, 2023Introduction to Injection Molding Injection molding is also known as injection molding, which is a kind of injection and molding method. The advantages of injection molding method are fast production ...view

- What Are the Applications of 4-Axis CNC Machining Services?September 14, 2024About 4-Axis CNC Machining ServicesIn 4-axis CNC milling, the fourth axis is added to the movement of the cutting tool, allowing it to rotate around the x-axis. Now, there are four axes: the x-axis, y...view

- What is the Tolerance of a 5 Axis CNC Machine?September 19, 2023What is 5 Axis CNC Machining?5 axis CNC machining is a type of computer-controlled machining that uses five axes of motion to cut and shape materials. The five axes allow for greater flexibility and p...view

- Timekeeping Triumphs: High Precision Tools in Watchmaking and HorologyJanuary 5, 2024In the intricate world of watchmaking and horology, where every tick of the clock is a testament to precision and craftsmanship, the role of high precision tools stands as the bedrock of excellence. T...view

- Optimize Product Development Cycle with Custom Prototyping ServicesJune 14, 2024Molds are indispensable basic technological equipment in the manufacturing industry, primarily used for efficient mass production of various industrial product components and parts. They are widely ap...view