Introduction to Sheet Metal Processing

Sheet metal processing is a pivotal technology that sheet metal technical staff needs to grasp, and it is also an important process for forming sheet metal products. Sheet metal processing includes traditional methods and process parameters such as cutting and downgrading, punching and cutting processing, bending and forming, etc. It also includes various cold stamping die structures and process parameters, various equipment working principles and manipulation methods, and also includes new stamping technology and new processes.

Sheet metal processing is called sheet metal processing. For example, sheet metal is used to make chimneys, barrels, oil tanks, ventilation pipes, elbows, small and large heads, round heads, funnel shapes, etc. The main processes are shearing, bending and edge-buckling, bending and forming, welding, riveting, etc., which require certain geometric knowledge. Sheet metal parts are thin sheet metal parts, that is, parts that can be processed by means of stamping, bending, stretching, etc. A general definition is that the thickness of the parts remains unchanged during processing. The corresponding parts are cast parts, forged parts, machined parts, etc.

Sheet Metal Processing Methods

Non-mold processing: A processing method for sheet metal by means of digital punching, laser cutting, shearing machine, bending machine, riveting machine, etc. It is generally used for sample making or small batch CNC machining production, and the cost is higher. Short processing cycle and quick response.

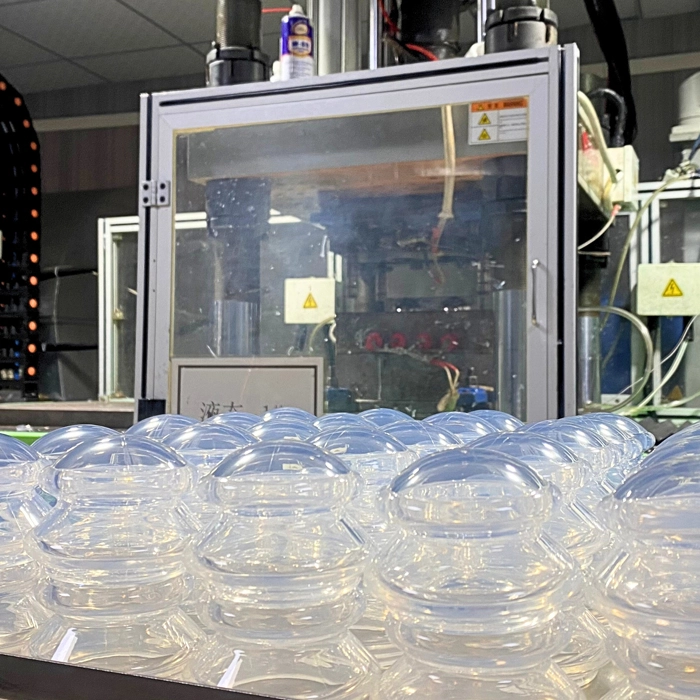

Mold processing: The sheet metal is processed by fixed molds, generally with undercutting mold and forming mold, mainly used for mass production and lower cost. Manufactured by prototype manufacturing companies, high front-end mold cost and guaranteed part quality. Long lead time for front-end processing and high tooling cost.

Sheet Metal Processing Flow

Downfeed: Digital punching, laser cutting, shearing machine

Forming: bending, stretching, punching: bending machine, punching machine, etc.

Other processing: press riveting, tapping, etc.

Welding: Sheet metal connection method

Surface treatment: Powder spraying, electroplating, wire drawing, silk-screening, etc.

- Prototype Machining Services: High-Efficiency Product OptimizationDecember 23, 2024What is Prototype Machining?Prototype machining is a manufacturing process used to create samples or prototypes of a product. It typically uses computer-aided design (CAD) software and computer numeri...view

- Applications of Precise Tool and ManufacturingSeptember 14, 2024About Ripple MFG's Precision Toolings ServicesAccording to Ripple MFG's global service strategy, it is dedicated to providing precision plastic injection molding services including...view

- Aerospace Advancements: Breaking Barriers with Precision Prototype MachiningJanuary 5, 2024As we continue to explore the boundless possibilities of space travel and aerospace engineering, one crucial element stands at the forefront of innovation – precision prototype machining. From pushin...view

- What Are the Process Steps for Cast Urethane Prototypes?September 14, 2024Polyurethane resin is a versatile material used to produce various plastic products. Its applications are diverse because it can produce both flexible, almost rubber-like products, and rigid plastics....view

- Development History Of Injection MoldingFebruary 27, 2023Introduction to Injection Molding Injection molding is also known as injection molding, which is a kind of injection and molding method. The advantages of injection molding method are fast production ...view

- What Are the Advantages of 5 Axis CNC?September 19, 20235 axis CNC machining is an advanced manufacturing process that utilizes five axes of motion to cut and shape materials. This technology is an improvement over the traditional 3 axis machining process,...view