The world of manufacturing and rapid prototyping has seen significant advancements in recent years. While 3D printing has gained immense popularity for creating prototypes and functional parts, there's another precision prototyping method that deserves its share of the spotlight—Precision Prototyping Machining. In this blog, we will take a closer look at this cutting-edge technique and why it's gaining traction in the manufacturing industry.

Understanding Precision Prototyping Machining

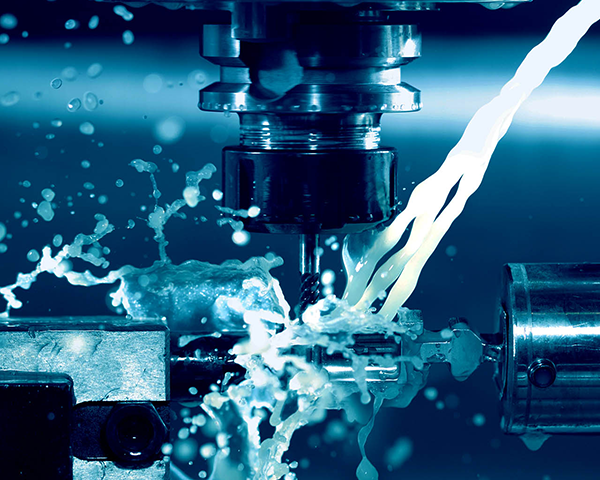

Precision Prototyping Machining is a subtractive manufacturing process that involves shaping materials to create a final product. Unlike 3D printing, which adds material layer by layer, machining removes material from a solid block to achieve the desired shape. This method is particularly well-suited for producing high-precision and complex components with tight tolerances.

The Advantages of Precision Prototyping Machining

Unmatched Precision and Accuracy

One of the key advantages of precision prototyping machining is its exceptional precision. It can achieve tolerances as tight as a few microns, making it ideal for applications where accuracy is paramount. Whether you're working on aerospace components or intricate medical devices, machining can meet your precision requirements.

2Wide Range of Materials

Unlike 3D printing, which is often limited to specific materials, precision prototyping machining can work with a wide variety of materials, including metals, plastics, ceramics, and composites. This versatility makes it a go-to choice for a broad spectrum of industries.

Superior Surface Finish

Machining can produce parts with a superior surface finish, such as CNC machining small parts, which is crucial for components that require a polished, high-quality appearance. This is especially important in industries like automotive, where aesthetics play a significant role.

Cost-Effective for Small to Medium Production Runs

While 3D printing excels in rapid prototyping and customization, machining becomes more cost-effective for small to medium production runs. The time and materials saved in this process make it an attractive choice for manufacturers looking to scale their operations.

Applications of Precision Prototyping Machining

Precision prototyping machining has found applications in various industries, including:

Aerospace: Crafting precision components for aircraft and spacecraft.

Medical: Manufacturing intricate medical devices and implants.

Automotive: Producing high-precision automotive parts.

Electronics: Creating complex components for electronics and semiconductors.

Defense: Developing critical defense and military equipment.

Tooling: Crafting molds, dies, and tooling for various manufacturing processes.

While 3D printing has revolutionized rapid prototyping and customization, precision prototyping machining is carving out its niche as the go-to method for achieving exceptional precision, working with a wide range of materials, delivering superior surface finishes, and being cost-effective for small to medium production runs. Manufacturers are increasingly recognizing the value of precision machining in their quest for high-quality, precise, and functional parts. As technology continues to evolve, precision prototyping machining is set to play a pivotal role in the future of manufacturing.

- Customized Prototyping in Aerospace InnovationMarch 19, 2024In aerospace, every technological innovation and breakthrough marks a step into the unknown. Ripple MFG, as a leader in this field, has injected new vitality into the development of the aerospac...view

- Timekeeping Triumphs: High Precision Tools in Watchmaking and HorologyJanuary 5, 2024In the intricate world of watchmaking and horology, where every tick of the clock is a testament to precision and craftsmanship, the role of high precision tools stands as the bedrock of excellence. T...view

- What Are the Process Steps for Cast Urethane Prototypes?September 14, 2024Polyurethane resin is a versatile material used to produce various plastic products. Its applications are diverse because it can produce both flexible, almost rubber-like products, and rigid plastics....view

- The Impact of Prototyping Machining Services in ArchitectureMarch 19, 2024With the advancement of science and technology, prototype machining services are increasingly used in the field of architecture, which has a profound impact on architectural design, construction and m...view

- What Are the Applications of 4-Axis CNC Machining Services?September 14, 2024About 4-Axis CNC Machining ServicesIn 4-axis CNC milling, the fourth axis is added to the movement of the cutting tool, allowing it to rotate around the x-axis. Now, there are four axes: the x-axis, y...view

- A Guide to CNC Prototype ManufacturingSeptember 1, 2023What is CNC Prototype Manufacturing?CNC prototype manufacturing is a type of prototype manufacturing that uses Computer Numerical Control (CNC) machines to create physical prototypes of products. CNC ...view