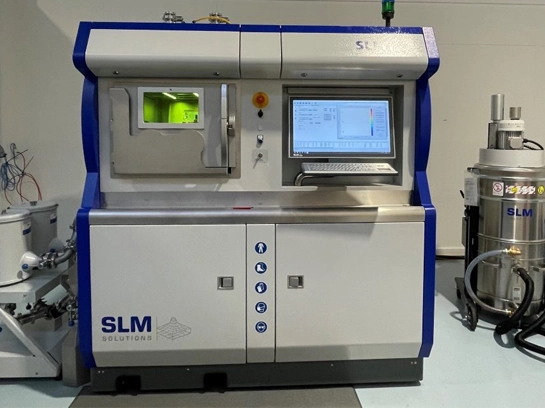

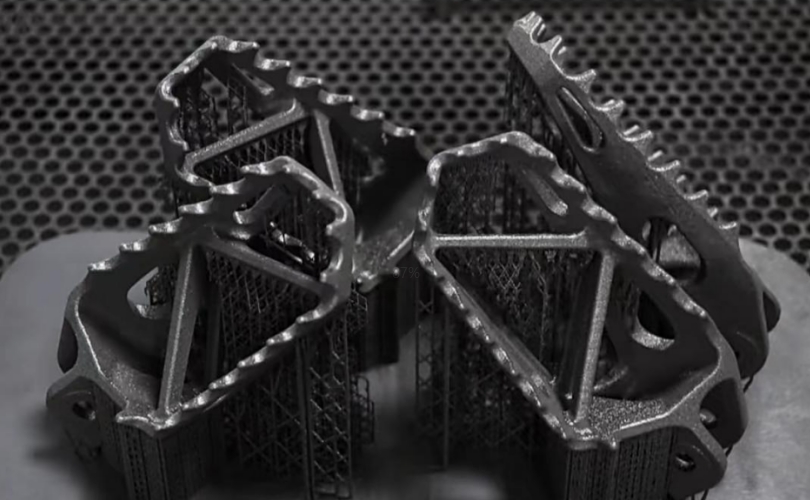

SLM is a metal 3D printing technology that uses a laser to fully melt fine metal powders, layer by layer, to produce dense, functional metal parts. This process creates parts with mechanical properties comparable to those produced by traditional manufacturing methods.

Aerospace and defense components: Lightweight and durable parts for high-performance applications.

Medical implants and prosthetics: Custom, biocompatible implants with complex geometries.

High-performance automotive parts: Engine components and other high-stress parts.

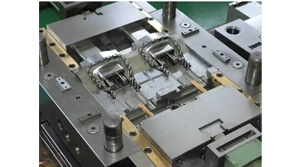

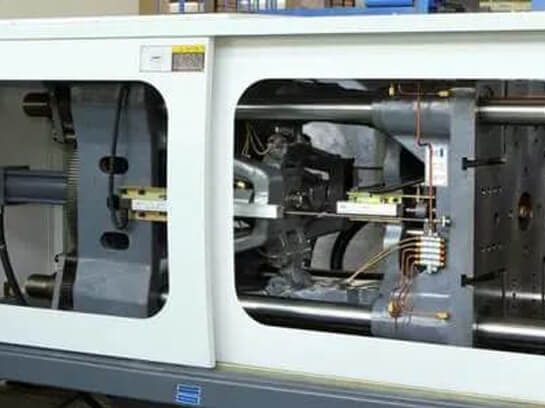

Industrial tooling: Custom molds, tools, and dies for manufacturing.

Produces fully dense metal parts with excellent mechanical properties.

Enables the creation of lightweight, complex geometries not possible with traditional methods.

Supports a wide range of metals for various applications.

High strength, durability, and temperature resistance.

Aluminum Alloys: Lightweight and corrosion-resistant, ideal for aerospace and automotive applications.

Stainless Steel: Strong, durable, and corrosion-resistant for industrial and medical uses.

Titanium Alloys: Lightweight, biocompatible, and incredibly strong, perfect for aerospace and medical implants.

Inconel (Superalloys): High-temperature resistance for aerospace and high-performance industrial applications.